PIPE COMPONENTS

Whether bent or straight, briar or meerschaum, the components of a good pipe, as illustrated above, are basically the same.

BOWL

The bowl of any pipe must be capable of resisting very hot temperatures and flame over long periods of time. For this reason, the bowl must be carved to perfection. The chamber wall must be consistent in thickness and density to prevent embers from burning through the wall. Great pipe making begins and ends with the bowl; without a finely crafted bowl the pipe will never work properly.

The chamber of a briar bowl can be finished in a variety of ways, including pre-carbonized, natural, and stained. A natural bowl will have no stain or finish applied; it will be sanded smooth or rough, depending on the makers preference. A stained bowl will have a color stain applied to give the inside of the bowl an attractive tint like the outside of the bowl. This process is considered a waste of time by many since the bowl will char and carbonize soon after the pipe is smoked. In addition, it is possible the stain may impart some flavor to your tobacco before the bowl chars and forms its own protective finish: carbonization. Pre-carbonization is a modern finish which mimics the carbonization process, and leaves a thin coating on the interior wall of the chamber. Pre-carbonization is useful if the chamber has aesthetic or structural imperfections which the maker would like to hide. Otherwise, no chamber finish is necessary for a high grade briar.

Stained |

Natural |

Pre-Carbonized |

SHANK

The shank of a pipe protrudes directly from the bowl, connects to the stem, and is typically carved from the same piece of briar (or meerschaum). Great care is taken when carving the shank, since it is part of the bowl and its grain and form must compliment the pipe. A well carved shank will be perfectly aligned with the bowl and stem: it will not curve left or right, unless intended. Additionally, the shank is the weakest part of the pipe since it is thin and has an air hole drilled through it. Shanks come in a variety of shapes, typically chosen to compliment the design of the pipe.

STEM

The stem of a pipe incorporates the air hole, lip, bit, and tenon, which connects to the briar at the shank; typically through tenon and mortise craftsmanship to ensure a tight and long lasting fit. Stems vary in shape and nuance as much as the pipes themselves.

Many great pipe makers go to great lengths to ensure that their stems are perfectly crafted to suit the pipes they serve. Amber, lucite, and vulcanite are the most common materials for making stems: these materials can be shaped easily and each have their respective pros and cons. | |

|

STYLES

There are two general style classifications for pipes: straight and bent. A straight pipe has a straight shank and stem and will be more inclined to directly transmit heat and moisture to the palate. A bent pipe has a curved shank and stem and tends to collect more moisture at the bottom of the bowl, below the bend of the shank. Both styles have a distinct feel and balance in the hand and mouth, which pipe smokers appreciate for different occasions or moods.

Straight Pipe |

Bent Pipe |

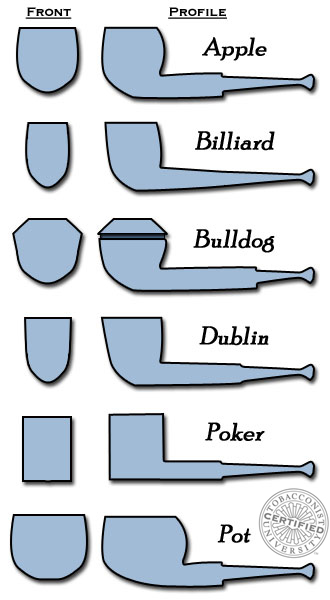

SHAPES

The majority of pipes today are based on half a dozen basic shapes. These shapes can incorporate straight or bent styles and can be squished, stretched, or manipulated to create new or different shapes.

| |

Calabash Style

The original calabash pipe, made from African gourds, was popularized in Britain during the 1800s. The gourds are trained by hand, while they grow, to attain the perfect "S"-like shape for pipe making. This process, and the large volume of space within the gourd, creates a shape that provides a cool smoke. Because the gourd cannot sustain extreme heat, calabash pipes typically have a removable bowl insert (briar, meerschaum, ceramic, etc...) for the tobacco to be placed in. Today, the term "calabash" refers to any pipe in the classic gourd "S"-like shape.

|

|

FREEHAND

Also known as sculpted or freestyle, freehand pipes do not conform to traditional pipe shape conventions. Freehand pipes are “sculpted” organically, allowing the grain and briar to dictate the shape and style of the pipe. For this reason, freehand pipes are frequently made completely by hand. It takes great skill and artistry to create an exquisite freehand, but the results are indisputably beautiful, as shown below.

Freehand By: Preben Holm |

Freehand By: Tim West |

Certified R&D Tobacconists: United States |

|

|

|

|

|